Study on plasma permeability of porous ceramic materials

Zinc oxide (ZnO), as a high band gap semiconductor, has been widely used in gas sensing and catalysis fields due to its excellent chemical stability and biocompatibility, especially t-ZnO with three-dimensional porous skeleton structure. By controlling the crystal morphology and defect structure of t ‐ ZnO, it can adapt to different applications, including plasma surface modification of zinc oxide to improve its conductivity and other properties. In order to combine the advantages of three-dimensional porous t ‐ ZnO with plasma surface modification, plasma must penetrate into the porous skeleton structure. Because high-energy plasma will cause the dissociation of C-C and C-H bonds on the polymer surface and attach new atoms or groups to the C radical sites, polymers can usually be used as markers of plasma treatment. In this paper, a method using ethylene propylene diene monomer (EPDM) as a marker was proposed to investigate the permeability of plasma to three-dimensional porous materials. By studying the plasma permeability of t-ZnO material with 90% porosity in oxygen low voltage capacitance coupled plasma, it is proved that different density materials and different treatment conditions have significant effects on the plasma penetration depth.

1) For plasma surface treatment, plasma itself will also be strongly affected by plasma surface interaction (such as secondary electron emission);

2) The permeability of plasma to t ‐ ZnO three-dimensional skeleton material decreases with the increase of sample thickness and t ‐ ZnO mass density.

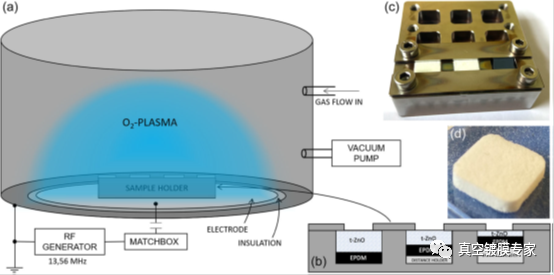

In order to ensure that ZnO samples with different thicknesses have the same plasma conditions when exploring the influence of ZnO thickness on plasma permeability, the oxygen low-voltage capacitive coupling discharge chamber, stainless steel sample bracket and t ‐ ZnO sample as shown in Fig. 1a-d were constructed. It is impossible for the plasma to directly reach the EPDM surface without penetrating t ‐ ZnO samples. In order to deeply understand the osmotic substances (sub or neutral components, such as atomic oxygen, molecular oxygen or ozone), different plasma sheath structures are formed in front of t ‐ ZnO/EPDM substrates using sample supports of different materials and at different positions in the plasma chamber. The structural changes of the sheath can be observed with the naked eye in Figure 2. As to whether plasma plays a role in surface modification of t ‐ ZnO materials, a simple and fast water contact angle (WCA) test is used to measure the change of surface tension caused by plasma penetration into t ‐ ZnO materials.

Fig. 1. (a) Setting of plasma chamber; (b) Schematic diagram of test sample holder: ethylene propylene diene monomer (EPDM) is covered with t ‐ ZnO, and the plasma cannot directly reach the surface of EPDM without penetrating t ‐ ZnO samples; (c) The photo of the stainless steel sample rack after filling. There are zinc covers on the left and middle samples, and the original EPDM rubber is on the right; (d) Photograph of 2.5mm thick t ‐ ZnO sample

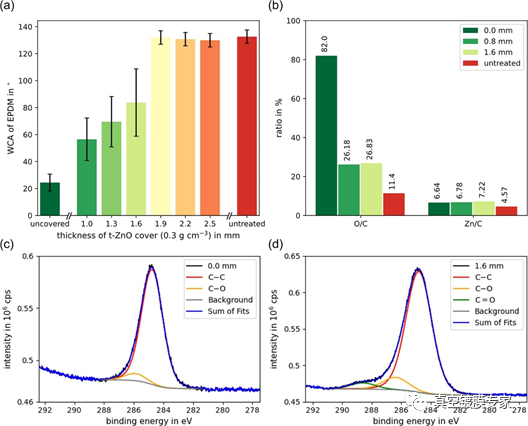

Figure 3 shows the characterization results of t ‐ ZnO coatings with different thicknesses, including the WCA and XPS results of EPDM surface after plasma infiltration. It can be seen that the WCA results of the 1.0-1.6 mm thick t ‐ ZnO coating have a large error bar, which may be due to the uneven porosity of the porous material, resulting in a large difference in the treatment effect of EPDM. However, some increasing trends of WCA can be determined. Therefore, the thinner t ‐ ZnO overburden has better permeability. Plasma can permeate through porous t-ZnO network, and the increase of EPDM surface wettability can be attributed to the functionalization of polymer rather than the residual t-ZnO on the surface. In addition, the plasma permeability will decrease with the increase of the mass density of t ‐ ZnO skeleton structure, and ions are the dominant particles penetrating the porous network structure. When t ‐ ZnO (mass density 0.3 g/cm3) is directly placed on the stainless steel bracket of the RF electrode, its penetration depth is about 1.6 mm. The use of Teflon stents shows a greater penetration depth of 2.5 to 4 mm. The t ‐ ZnO sample can be directly exposed to the plasma on the RF electrode for several times to improve the magnetic permeability.

Fig. 3 Characterization results of t ‐ ZnO coatings with different thicknesses: (a) WCA and XPS results of EPDM surface after plasma penetration; (a, b) Data including unprocessed EPDM (red) and uncovered EPDM (dark green); (c) High resolution scanning of C1s peak of uncovered EPDM after plasma penetration; (d) High resolution scanning of C 1s peak of EPDM covered by 1.6 mm t ‐ ZnO during plasma permeation

18922924269

18922924269