Xinbo Technology (Dongguan) CO., LTD

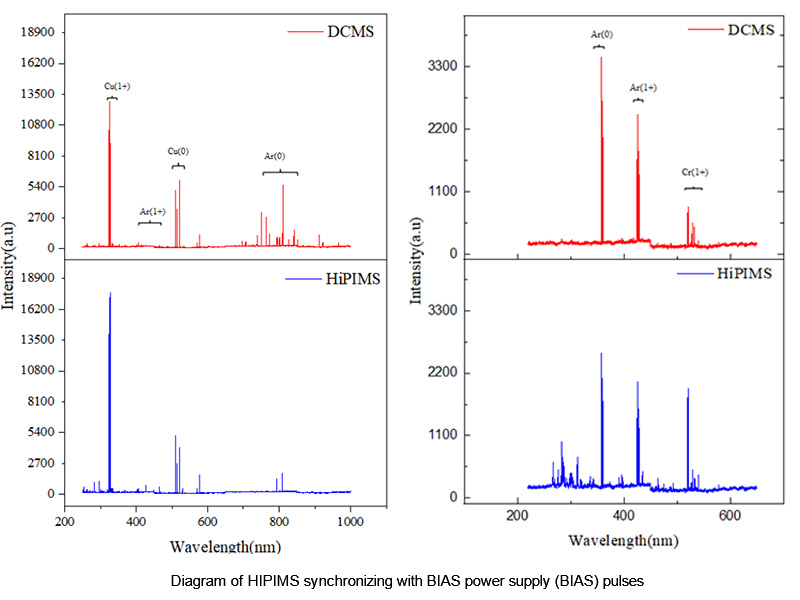

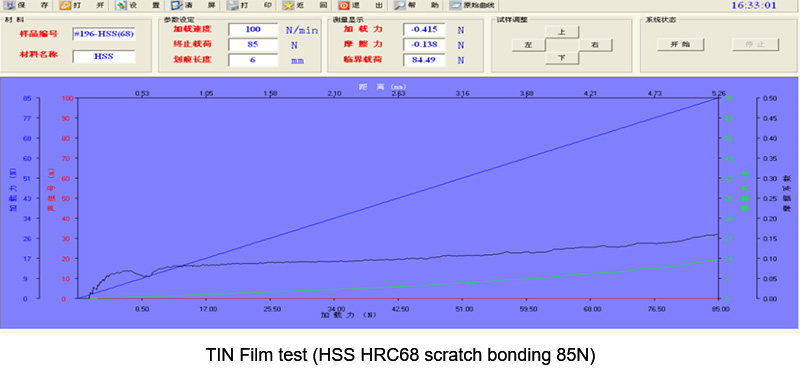

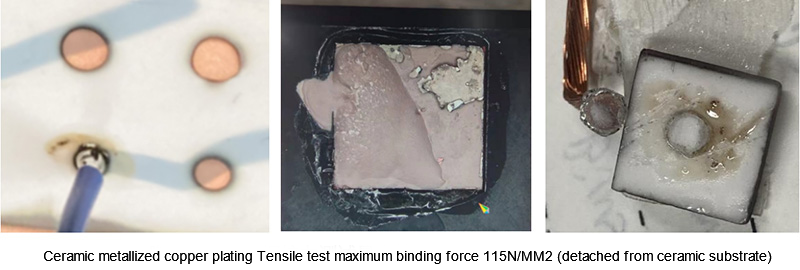

Combined the high ionization rate of HiPIMS and the synchronization of pulse bias power, the energy and distribution of metal ions can be synchronously controlled. Performing metal ion etching and cleaning on the substrate to achieve high adhesion strength of film deposited on the metal, ceramic, glass, optical fiber and other insulating substrates. The critical load of TiN film deposited on high-speed steel is 85 N, and the adhesion strength of the Cu film deposited on the ceramic substrate reaches 115 N/mm2.

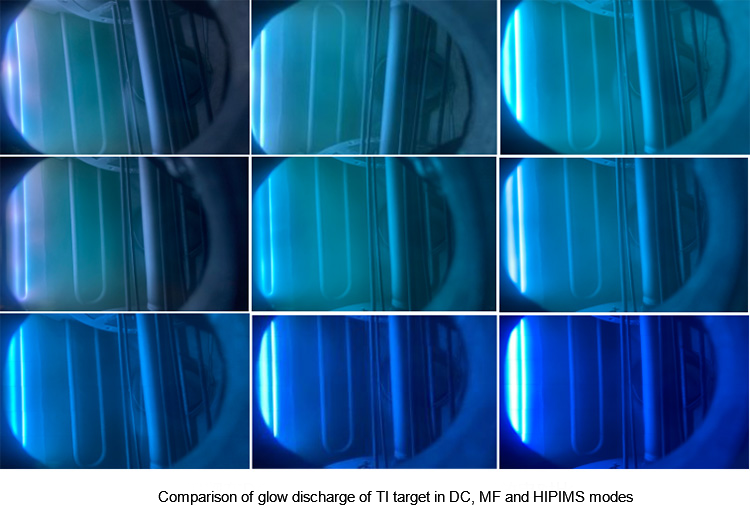

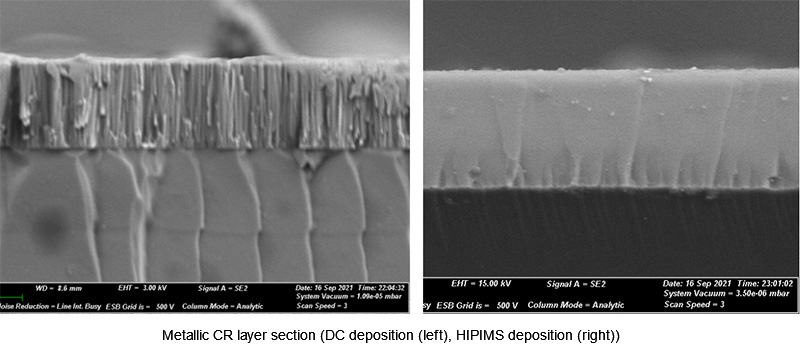

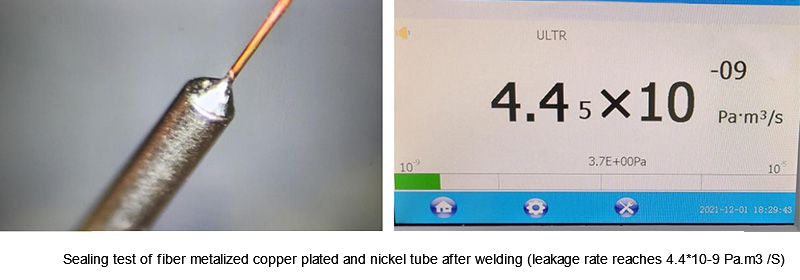

The high ionization rate of HiPIMS makes it easier to control the bombardment of metal ions when depositing hard or metal coatings and achieve high-density growth of the film. Compared with the traditional DC/MF mode, the film section is dense and smooth. After the fiber metallization welding, the sealing performance test of the film can reach 4.4×10-9 Pa.m3/s.

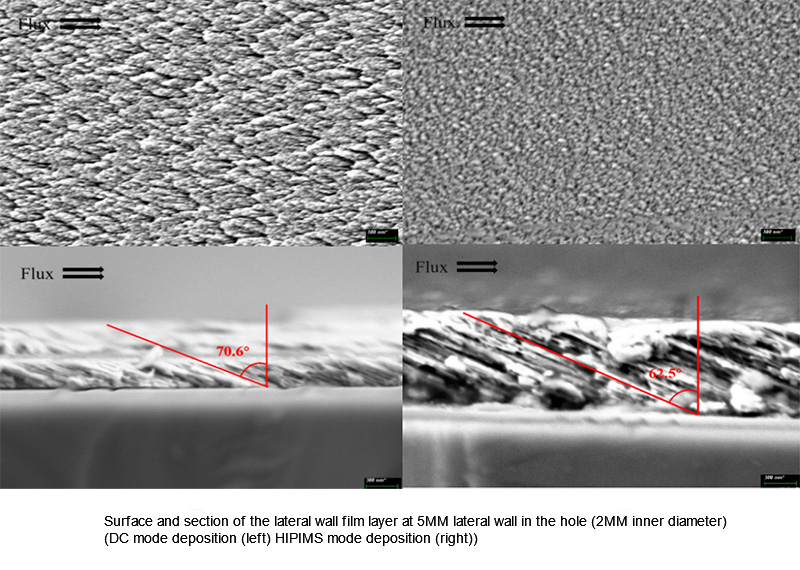

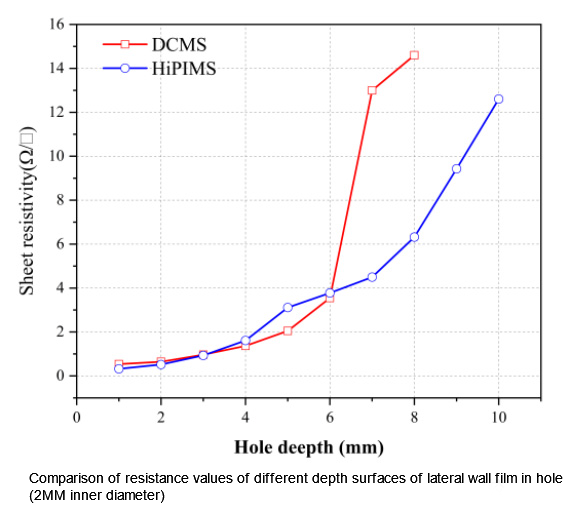

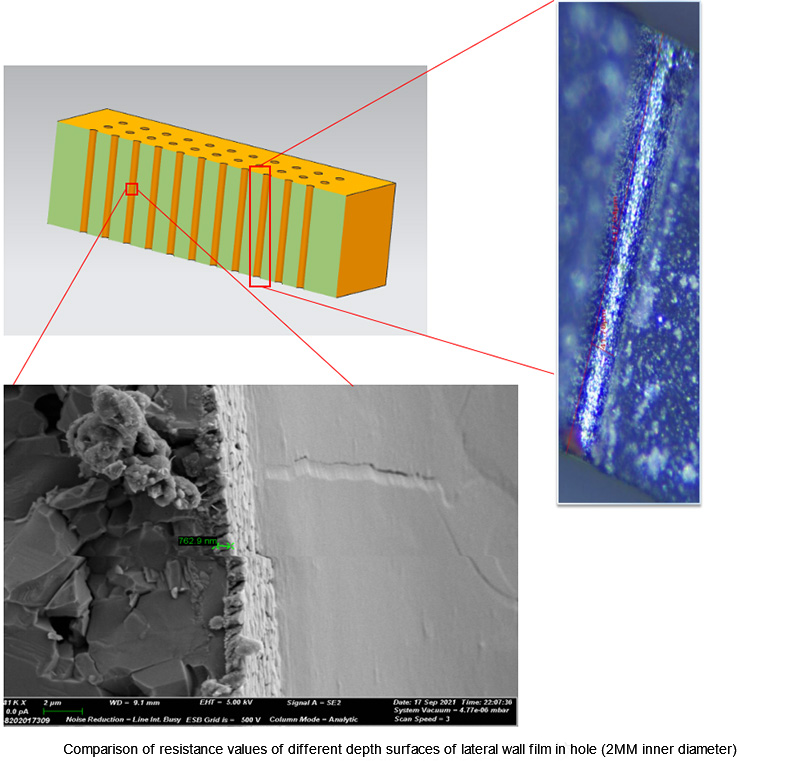

The HiPIMS power supply instantly forms a high peak current and forms a high-density plasma, which greatly improves the uniformity of the film deposited on the the heterosexual workpiece. A uniform and dense film can also be prepared inside shapes such as sides, concave holes, and through holes. The HiPIMS technology deposits a dense and smooth film on the inner sidewall of the hole, and the square resistance of the metal layer in the hole is more uniform and lower.

Cooperating the ultra-high-density plasma formed by the HiPIMS and the synchronization of the pulse bias, the metallization of the inner surface of the micro-deep hole (a pore diameter of 40 μm and a hole depth of 500 μm) was realized by the metal ion sputtering deposition and etching. The metallized film is uniform and dense on the inner surface of the ceramic micropore (the aspect ratio is 12), which is close to vertical growth.

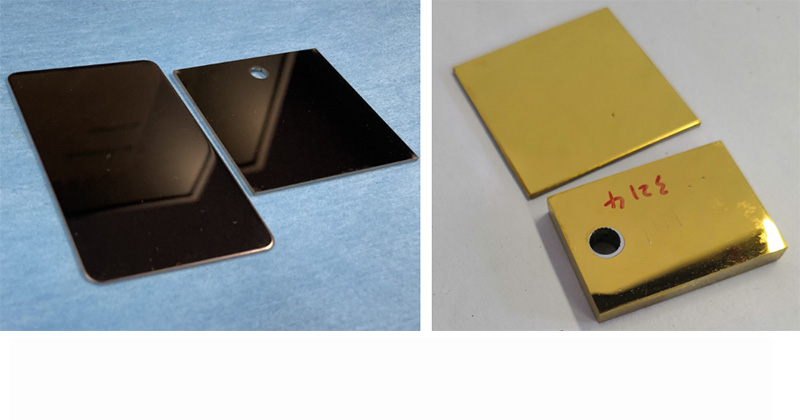

The ultra-high-density plasma formed by HiPIMS generates the high ionization rate of target material and reactive gas, resulting in the high-density and smooth surface of the film. The brightness of TiN film prepared by HiPIMS reaches 76.3, which is 8 points higher than the conventional MF brightness value. The L brightness value of the rose- gold TiCN reaches 65, which is close to the brightness value of multi-arc decorative plating.

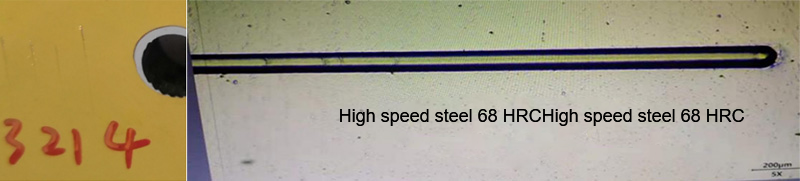

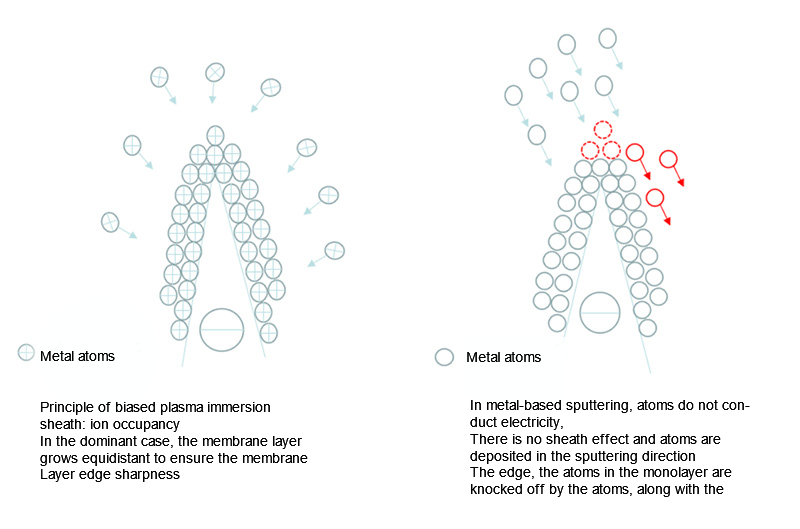

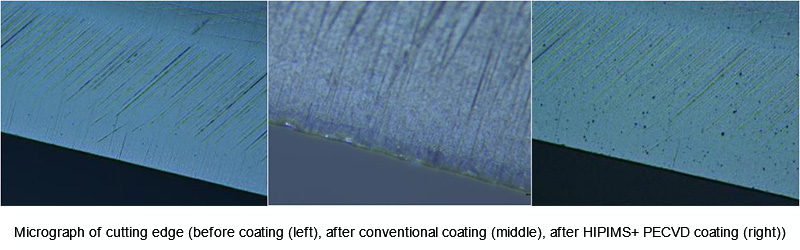

Due to the HiPIMS technology, the film layer evenly wraps and grows at the cutting edge, which can maintain the sharpness of the cutting edge; Combined with PECVD method to prepare low-damage DLC coating, hardness 1500Hv, low friction coefficient At 0.15, HSS binding force is HF1, doping Ag and Cu have antibacterial effect.

Multi-arc rose gold: 66.8, 10.8, 11.8 (left) SUS 77.4,9.5,43.7

Preparation of rose gold by HiPIMS: 65, 10.2, 13.9 (right) HSS 76.2, 9.8, 42.2 (bottom)

Principle of biased plasma immersion sheath: ion occupancyIn the dominant case, the membrane layer grows equidistant to ensure the membraneLayer edge sharpness

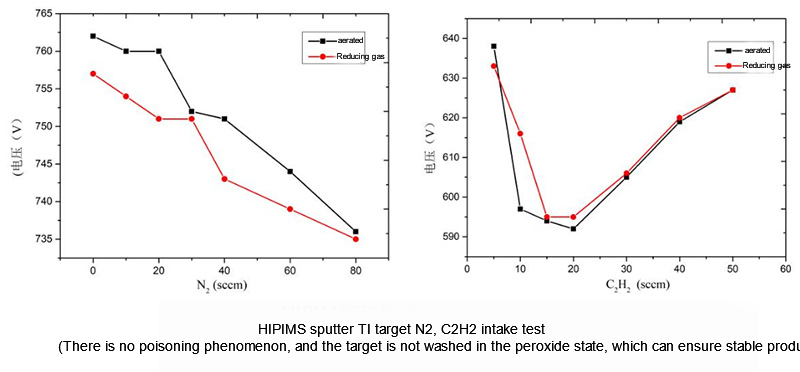

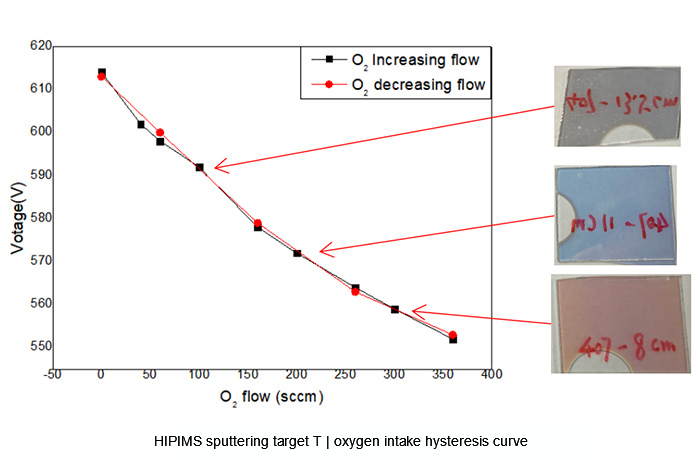

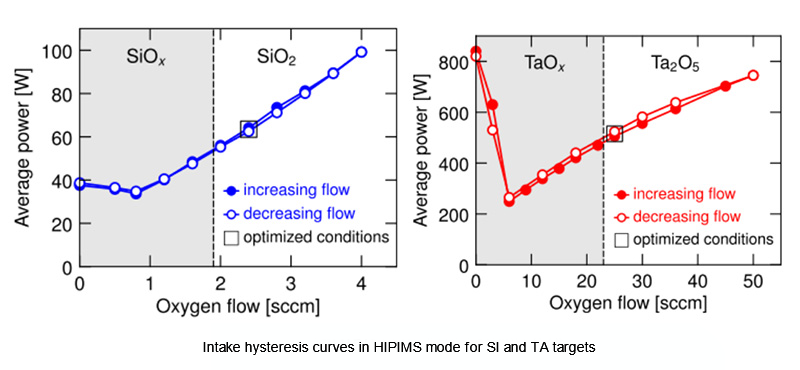

Due to the high ionization rate of target in HiPIMS progress, there is no target poisoning and hysteresis curve phenomenon during the reactive sputtering between oxygen and targets (Ti, Nb, Si). Thus, the prepared optical film has high density, high refractive index and low stress.

18922924269

18922924269