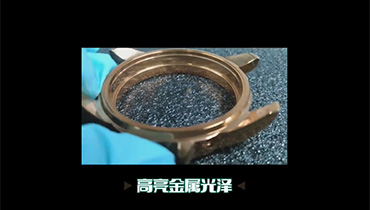

Decorative coating for watch

New Platinum Technology (Dongguan) Co., Ltd. focuses on high energy plasma surface engineering hardware and technology.

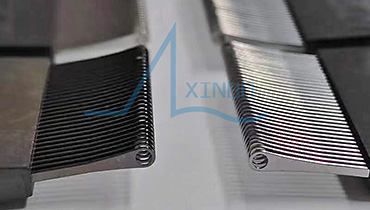

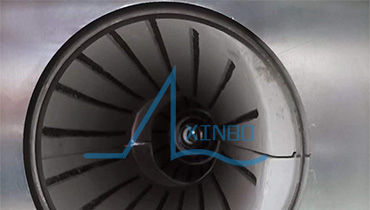

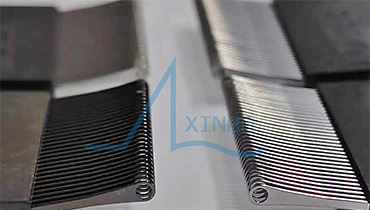

Coating of kitchen knife edge display

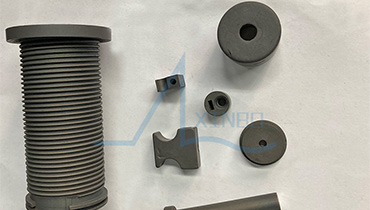

Video takes you to learn about new Platinum technology tool coating

Classification of vacuum coating films

Vacuum coating technology is generally divided into two categories, namely physical vapor deposition (PVD) technology and chemical vapor deposition (CVD) technology.

Application field of vacuum coating technology

With the development of the economy and the improvement of living standards, people like the hand watch case, watchband, clothing, lighting, glasses frame, indoor and outdoor

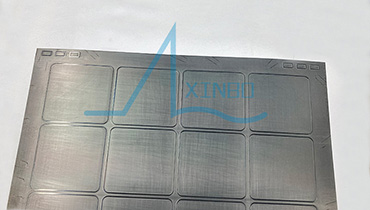

Advantages and uses of vacuum coated glass

PVD metal vacuum coating has the advantages of strong binding force, long color protection time and strong wear resistance, which is superior to traditional electroless plating to a certain extent. So can this vacuum coating process replace the traditional chemical coating process? The answer is no, at least for now.

Vacuum coating equipment industry competition pattern and facing opportunities and challenges

Vacuum coating technology from abroad, with the first mover advantage and a large amount of investment in R & D funds, international enterprises in the global vacuum coating equipment development and production market is still in a position. In the international market,

What is vacuum coating?

Preparation of vacuum films, including metal, semiconductor, insulator and other elemental or composite films. Although chemical vapor deposition also uses vacuum means such as vacuum pressure, low pressure or plasma, the general vacuum coating refers to the deposition of thin films by physical methods. Vacuum coating has evaporation coating,

0769-81001639

0769-81001639