A diamond-like coating was prepared on the inner wall of the pipeline using an anode ion source

Anodic layer ion sources have been widely studied due to their simplicity and ability to convert gas into an ion beam, the main function of which is the continuous generation of an ion beam over a 360° range during use. The coating on the inner wall of a pipe can be prepared by simply pulling the ion source along a straight or curved pipe. Diamond-like (DLC) coatings prepared by traditional physical vapor deposition methods such as DC/RF magnetron sputtering and PLD usually contain structural defects such as pinholes, holes and cracks. However, the high energy dissociation and ionization energy in the anode ion source reduce the presence of macroscopic carbon particles in the carbon target, so as to obtain a high-quality and defection-free DLC coating. The poor binding strength between DLC coating and substrate also limits its application, and the internal stress of coating is the key to the poor binding strength. The bonding force of DLC coating can be greatly improved by using multi-energy injection in the anode ion source coating.

1. The disorder degree of DLC coating prepared at lower energy (7 kV) is slightly higher, indicating that the content of sp3-C bond is larger;

2. The DLC coating prepared with higher energy is likely to have better atomic mixing on the interface layer, so as to improve the binding force of the coating.

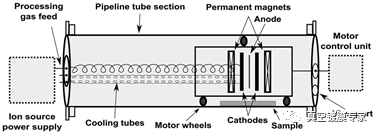

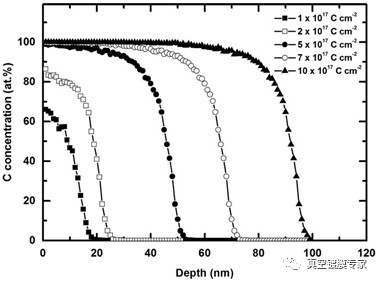

DLC coating was prepared on the inner surface of the pipeline with a circular anode layer ion source as shown in Figure 1. The anode voltage was 3-8 kV, and the deposition rate was up to 70 ± 10 nm/min. As shown in FIG. 2, the energies of each H and C atom in the ion beam were calculated at an anode voltage of 8 kV. C3H8+ was considered as the main ion species to obtain the depth distribution of C atoms with an energy of 2.2 keV in Fe, the main component of stainless steel. According to the calculation, its projected range is about 3.8 nm, while 180 eV H penetrates only 1.8 nm from the surface. Due to the higher energy of each C atom (~ 7.4 keV) associated with the CHX+ ion beam, the penetration depth of the stainless steel substrate is expected to reach 10.4 nm. When the carbon atom flux reaches 5 × 1017cm−2, a layer of carbon will be formed on the substrate, and its sputtering rate is < 1.

Figure 1. Schematic diagram of a pipe coating system with a circular anode ion source.

Figure 2. Dynamic correction calculation of the effect of C atoms with an energy of 2.2 keV on Fe matrix in the range of 1 × 1017~1 × 1018 C cm−2.

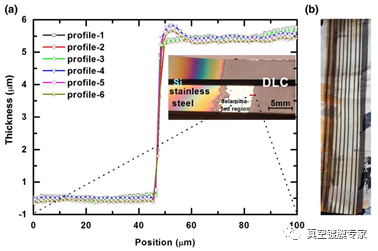

Figure 4a shows the profiles of DLC coatings on stainless steel and Si substrates at 8 kV and 3 kV anode voltages. When the anode voltage is 3 kV, the DLC coating delaminates from the stainless steel surface, but still exists on the Si substrate, indicating that its binding strength to Si is good. However, the DLC coating with dual energy deposition has good binding force on the surface of stainless steel, which indicates that multiple energy deposition is beneficial to enhance the binding strength of the coating on stainless steel and other substrates. Figure 4b shows the trajectories of the DLC coating on the tinfoil placed in the pipeline at different energies, and it is clear that the 360° uniform deposition of the DLC coating on the inner wall of the pipeline can be achieved using a radial anode layer ion source.

Figure 3. (a) profile of DLC coating and (b) omnidirectional trajectory of DLC coating under different energies.

The multi-energy deposited DLC coating can provide better bonding strength on substrates with large differences in thermal expansion coefficients

1.P. P. Murmu, et al. A novel radial anode layer ion source for inner wall pipe coating and materials modification--hydrogenated diamond-like carbon coatings from butane gas. Rev Sci Instrum. 2014, 85 (8), 085118.

Literature (contributed by xdz)

18922924269

18922924269