Comparison of TiAlN thin films prepared by HiPIMS and dcMS on the inner surface of micropores

New platinum technology, focusing on high energy plasma surface engineering hardware and processes.

Lube oil is commonly used to improve the service life and machining accuracy of microforming (the miniaturization of metal stamping process size) molds, but from the perspective of dirt treatment, product contamination and unstable formability, lube free microforming processes are a strong demand in the industry. This requires uniform preparation of a lubrication protective film with adhesion resistance, high toughness and wear resistance on the inner surface of the mold micropores. Although CVD technology has greater advantages over PVD technology in non-planar uniformity, the film properties and substrate temperature are not suitable for micromold manufacturing. High energy pulsed magnetron sputtering (HIPIMS) technology is a novel PVD process which can obtain high ionization degree. By using this technology to prepare hard wear-resistant coating on the inner wall of micropores, the low efficiency (scale effect) of lubricants in micro-scale forming can be solved. Compared with the traditional dcMC (DC magnetron sputtering) technology, the TiAlN films deposited by HIPIMS have dense microstructure, smooth surface, and higher hardness even in the inner wall of micropores. In addition, the friction test and scratch test also show that the film has good wear resistance and bonding strength on the substrate. At the same time, compared with dcMS, the micromold deposited by HIPIMS has better adhesion resistance.

1) Compared with dcMS, the ionic energy of HIPIMS plasma is higher, the distribution is wider, and the film has better uniformity on the inner surface of micropores and ultra-compact structure;

2) Due to the high initial kinetic energy of HIPIMS plasma sputtered particles, the effective momentum transfer during the film growth process was induced, and the mobility of adsorbed atoms was improved.

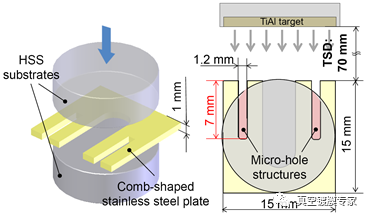

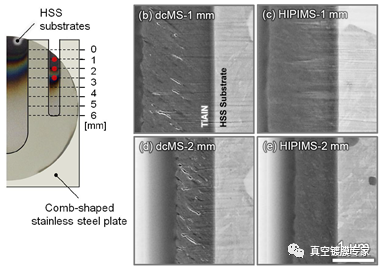

In order to simulate the micro-pore structure of the micro-forming die and realize the closure function of sub-millimeter scale, the comb stainless steel plate was sandwiched between two HSS substrates, and a micro-pore with an area of 1mm × 1.2mm and a depth of 7mm was realized, as shown in Figure 1. The properties of microporous inner wall films at a depth of 1-3 mm from the orifge (FIG. 2a) were studied in detail. FIG. 2 b-e shows the FE-SEM cross section image of TiAlN thin film when the inner wall was deposited 1 and 2 mm away from the entrance of the micropore. Due to the porous microstructure, the density of dcMS films is relatively low. According to Monte Carlo simulation results, the shadow effect of the slanted substrate leads to a decrease in the film density of the slanted structure, which indicates that the ions deposited in the dcMS have a relatively low energy. However, the TiAlN films deposited by HIPIMS showed significant compact structure at 1 mm and 2 mm. The vertical growth of the film in HIPIMS deposition is mainly dependent on the substrate bias to regulate the ionization flux of the metal. Due to the high initial kinetic energy of HIPIMS plasma sputtering particles, the effective momentum transfer during the film growth process is induced and the mobility of adsorbed atoms is improved. In addition to the metal ion bombardment effect, these energetic particles contribute to the densification of film growth even at the side walls of small pores in the submillimeter range.

Figure 1. Schematic diagram of HSS substrate structure with sub-millimeter scale holes.

FIG. 2. FE-SEM cross section images of TiAlN films deposited on the inner surface 1 mm and 2 mm from the entrance of micropores using dcMS and HIPIMS. (a) Observation of the position and HSS substrate at deposition; (b) dcMS-1 mm; (c) HIPIMS-1 mm; (d) dcMS-2 mm; (e) HIPIMS-2 mm.

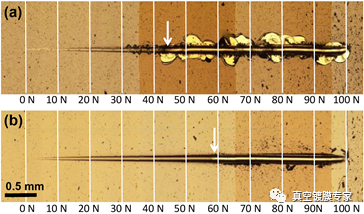

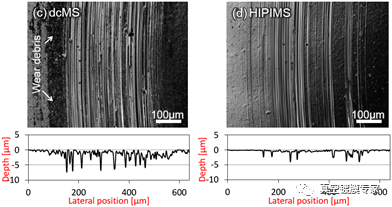

Figure 3 shows the scratch and abrasion results of TiAlN films prepared by dcMS and HIPIMS. Because the proportion of high-energy ions in the HIPIMS process is higher than that in dcMS, HIPIMS plasma improves the cleanliness of the substrate surface and enhances the adhesion of the film. Compared with HIPIMS films, TiAlN films deposited by dcMS have more serious abrasive wear. The oxygen-rich grinding chips from the SUJ2 steel ball accumulate at the edge of the wear track and oxidize due to high temperature. The hard iron oxide particles will form a three-body wear mechanism. At the same time, due to the low hardness of the dcMS deposited film, the wear of the film increases. In addition, due to the formation of TiO2, Al2O3 and other oxides by the wear chips of the film, further wear of the dcMS film occurs. Due to the high density and high hardness of HIPIMS deposition film, the three-body abrasive wear in the sliding process can be inhibited. In conclusion, TiAlN thin films prepared by HIPIMS have more advantages than dcMS deposition in terms of bond strength and wear resistance.

Figure 3. Scratch and abrasion results of TiAlN films prepared by dcMs and HIPIMS

18922924269

18922924269