Influence of different precursor gases on DLC film

In the process of DLC film preparation, hydrocarbon precursor gases are used, and different precursors have different effects on the performance of the film.

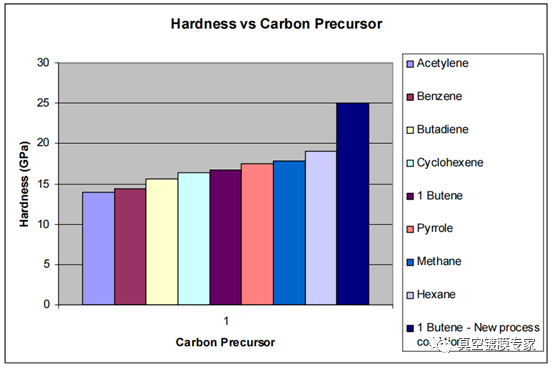

The effects of a series of hydrocarbon precursors on film hardness, bonding strength and deposition rate were evaluated. The film hardness is increased from 15GPa of acetylene to 25GPa of butene, and the deposition rate is kept high.

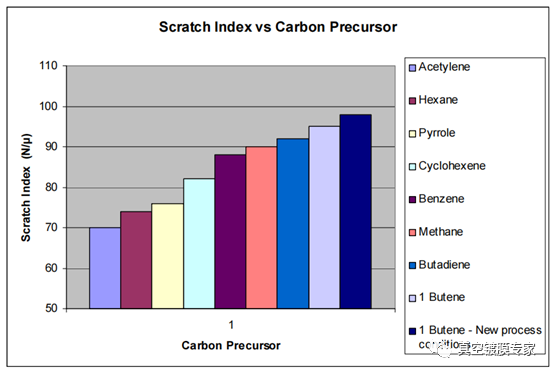

Eight different gaseous hydrocarbon precursors were used to evaluate and characterize the high hardness, deposition rate and binding ability of the films. Hydrocarbons were chosen to contain single -, double -, and triple-bonded carbons and different ratios of hydrogen/carbon in the precursor molecules. All precursors were evaluated using the same process conditions. It can be seen from Figure 1, 2 and Table 1 that butene has the best binding strength, hardness and deposition rate. Sp3 content was determined by Raman spectroscopy, and hydrogen content was determined by hydrogen forward scattering (HFS).

Then the process conditions were optimized, and the hardness was further significantly increased by nearly 50%, with only a slight decrease in the deposition rate. A trend was observed in the hardness data based on the saturation of the molecule. Fully saturated molecules (methane and hexane) have higher hardness, while less saturated molecules have lower hardness, such as triple-bonded acetylene has the lowest hardness, and multi-double-bonded benzene also has lower hardness.

DLC film

Figure 1: Hardness comparison of films prepared with different carbon precursor gases

Figure 2: Comparison of scratch index of film prepared with different carbon precursor gases

The deposition rates of methane and hexane were the lowest, while the deposition rates of acetylene and benzene were the fastest. The high deposition rate of unsaturated hydrocarbons can be explained by the more active nature of PI bonds and the possible formation of more active radicals in the plasma.

The reason for the reduced hardness, explained by Raman data, could be that these same PI bonds in the precursor lead to the formation of a more SP2-rich coating. Sp3 content and precursor saturation also showed a similar trend. Sp3 content measured by Raman spectroscopy increased with the increase of precursor saturation. The hardness did not increase with the decrease of hydrogen content of precursor gas, which indicated that the hardness was dominated by precursor saturation. The results show that the hardness is mainly due to hydrocarbon precursor saturation rather than ionic energy or hydrogen content.

DLC film

summary

Depending on the selection of hydrocarbon precursors, the hardness, deposition rate and binding force can be controlled. According to the law observed for the saturation degree of hydrocarbon precursors, saturated hydrocarbon precursors produce harder coatings with slower deposition rate, while unsaturated hydrocarbon precursors produce softer coatings with faster deposition rate.

18922924269

18922924269