Effect of HiPIMS pulse waveform on glow discharge characteristics

The introduction

HiPIMS power supply is a kind of pulse power supply. By reducing the duty cycle to less than 10%, the peak magnetron sputtering current can be increased by three orders of magnitude under the same power. This paper will introduce the influence of pulse waveform on glow discharge characteristics, so as to provide reference for controlling glow characteristics of different targets and process optimization.

Dot eyeball

1) In the process, it is often desired to obtain high peak current and low target voltage, but these two are often contradictory and need to be considered comprehensively in the process.

2)HiPIMS power supply has many adjustable parameters. Even under the same duty cycle, different characteristics of pulse width, duty cycle, target voltage and peak current will appear for different targets, which increases the difficulty of optimization while increasing the process control means.

3) The peak current density increases with the increase of target voltage, but the trend of peak current variation is different in different voltage segments.

4) Under long pulse width, metal discharge will enter the self-sustaining discharge mode, which will reduce the sputtering speed, but can increase the type and number of ions, which should be selected according to the process requirements.

conten

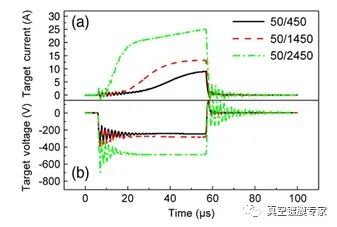

In Cr target magnetron sputtering, the pulse duty cycle is adjusted as low as 3.33% and 2% by increasing the pulse closing time to 1450US and 2450US. Under the condition that the average current remains unchanged, increasing the pulse cycle time will greatly increase the target voltage and peak current, as shown in Figure 1. As the voltage increases, the peak current duration also increases. Under constant power condition, different target voltage and peak current can be obtained by changing pulse structure, thus different plasma performance can be obtained.

FIG. 1 Influence of pulse shutdown time (duty cycle) on current and voltage

The most important factor affecting HiPIMS plasma performance is the peak current. Next, the relationship between different peak current and target voltage is introduced. The relationship between gas ions and metal ions at different peak currents.

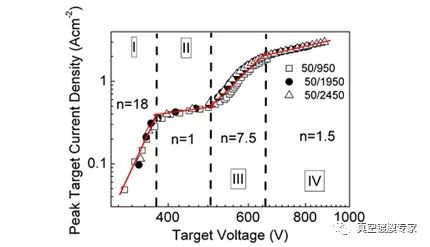

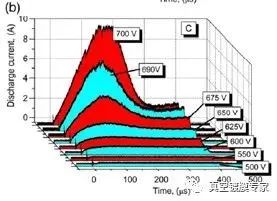

The relationship between voltage and peak current under different pulse duty cycles is shown in FIG. 2. The relationship between voltage and peak current can be divided into:

A. When the voltage is less than 400V, the peak current density increases by A factor of 18 with the increase of voltage (like DC plasma, the current density is less than 0.36A/cm2).

B. When the voltage is 400-550V, the peak current density is basically unchanged with the increase of the voltage, which mainly increases the impedance of the plasma

C. At 550V-650V, with the increase of ionization rate, the current density increases with the increase of voltage. D. When the peak current is greater than 1.6A/cm2, the binding and influence of the target magnetic field on the electron will basically disappear, and the peak current will become stable again.

FIG. 2 Relationship between voltage and peak current under different pulse duty cycles

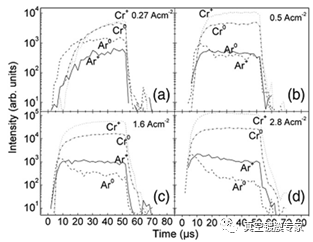

The relationship between gas ions and metal ions in different peak currents is shown in FIG. 3, which corresponds to the four stages of peak current density and the relationship between metal ions and gas ions in plasma intensity. A. At the minimum peak current, the number of gas ions and metal ions increases;

B. When the peak current is increased to 0.5 ACM-2, the intensity of Cr particles and ions will increase, but Ar ions will not.

C. When the peak current is increased to 1.6 ACM-2, the number of Ar particles begins to decrease, showing an obvious gas rarefaction effect.

D. When the current continues to increase, the gas rarefaction becomes more prominent, and the target surface glow is dominated by metal ions.

FIG. 3. Yield difference of gas ions and metal ions under different peak currents

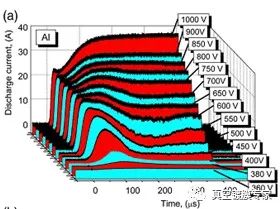

If target pulse time stretched, the relationship between the discharge current and voltage, there are two kinds of models, as shown in figure 4, for the material metal sputtering easily in a long time can be self sustaining discharge into the ablating model, after more than 750 v, basal discharge current of ion current even greater than the target, at the same time have a long enough time to produce a wider variety of charged particles, Like more divalent metal ions. Due to the low sputtering yield and high ionization potential energy of C, the target sputtering cannot maintain its self-sputtering mode. This is also the reason why the sputtering rate and ionization rate of C are relatively low. Long pulse times are not necessary for such materials.

FIG. 4 Relationship model of long pulse width discharge current and voltage, (a) metal mode (b) non-metal mode [3]

The change of current during long pulse time is not only related to the power and pulse structure, but also related to the secondary electron emission of the target. The secondary electrons produced in the sputtering process can also generate part of the current driven by the magnetic field. In other words, the power, pulse structure and some characteristics of the target, such as sputtering yield, ionization potential energy and the number of secondary electrons generated by sputtering, will directly affect the current duration. So there will be metals Al and nonmetals C that appear in different patterns.

conclusion

1) The general trend of the relationship between peak current and target voltage is that the peak current increases with the increase of target voltage, but the change trend is different. Between 400 and 550V, only plasma impedance increases;

2) At the peak current, metal ions and gas ions will separate in time;

3) Under long pulse width, metal discharge will enter the support discharge mode, which can increase the type and quantity of ions. For materials with high ionization energy, such as carbon, ionization cannot be increased even under long pulse width.

18922924269

18922924269