Bipolar HiPIMS regulates the growth of high density copper films

The introduction

As mentioned above in "Bipolar HiPIMS regulates ion Energy during Film Growth", adding a certain positive pulse to HiPIMS discharge after the completion of negative pulse discharge can improve the plasma potential after HiPIMS discharge, so as to accelerate the energy of ions reaching the substrate and improve the growth rate and quality of the film. What about the film formation rate and quality, compared to DC magnetron sputtering and conventional HiPIMS discharge? Here, we use sputtering Cu film to carry out experimental verification.

Dot eyeball

1) Using bipolar HiPIMS with forward pulse found that the deposition rate of Cu film could be increased;

2) The films prepared with bipolar HiPIMS containing forward pulses have higher compactness.

content

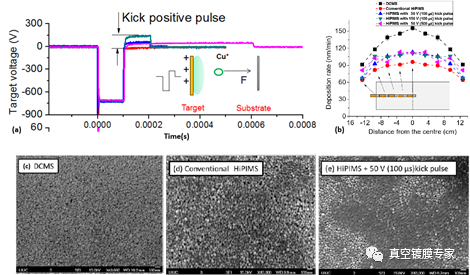

The bipolar HiPIMS discharge voltage waveform used in the experiment is shown in FIG. 1(a). After the negative pulse voltage discharge is completed, a certain positive voltage is added to improve the plasma potential in the area near the substrate, and then increase the ion energy flying to the substrate. Therefore, compared with the traditional HIPIMS, the deposition rate under the forward voltage is significantly increased, as shown in FIG. 1(b). It is also observed that when the ion energy is increased, we can get a more compact film. As shown in Figure 1(c), the Cu film under scanning electron microscope is looser than that under DCMS discharge, and the traditional HiPIMS can significantly improve the film compactness with fewer looser holes, as shown in Figure 1(d). However, bipolar HiPIMS can further reduce the number of holes to obtain higher density Cu films as shown in Figure 1(E).

Figure 1. Sem images of Cu film under different conditions of (a)HiPIMS voltage and (b)Cu film deposition rate (C-E).

extension

1) In the comparison results, we actually see that the uniformity of Cu film deposited under bipolar HiPIMS is also improved.

2) Not only Cu films, but also bipolar HiPIMS can improve other types of deposited films such as Ti,DLC, etc.

3) As for the coating process results, the increase of film density under bipolar HiPIMS means that the residual stress in the film is reduced. Will it also improve other properties, such as the increase of elastic modulus and corrosion resistance?

18922924269

18922924269