What does PVD preprocessing do to clean up?

The introduction

We all know that PVD pretreatment is very important, and it is even said that a good film plating may have more than 50% of the decision on pretreatment. So preprocessing, what do you get rid of?

content

1) Oil treatment: lubricating oil, cutting fluid, anti-rust oil, etc. adhered to during processing, assembly and operation

2) Water-based treatment: hand sweat during operation, water vapor during blowing, saliva, etc

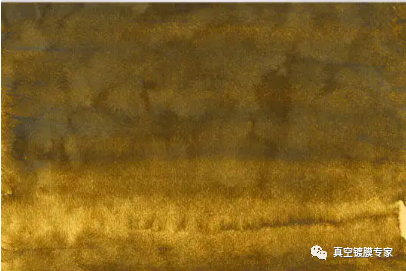

3) Surface oxide treatment: the surface oxide formed when the material is exposed to the air for a long time.

4) Acids, alkalis, salts: residual substances during cleaning, hand sweat, minerals in water, etc

5) Polishing residue and dust and other organic matter in the air, etc.

After understanding these problems, we can tell the user, try to pay attention to the processing, operation process and transportation process before coating.

You can understand why you need to wear a mask or special gloves when loading the furnace.

Even in the cleaning, drying or furnace transport to make good use of the cleaning car.

At the same time, special plasma cleaning means and technology should be adopted in the vacuum chamber. In this way, the surface of the coated material is exposed to the fresh active surface, so that there is a better atom-ion contact with the coated material.

If not paid attention to, these surface residues will reduce the binding force of the film and even inhibit the optimization of the film structure, which will eventually affect the film performance.

18922924269

18922924269