New application of HiPMS tool - high entropy alloy film manufacturing

High entropy alloy nitride film is a kind of product based on the design concept of high entropy alloy, which can have lower Gibbs free energy and lower element diffusion rate in thermodynamics and kinetics, respectively. It can inhibit the formation of ordered phase of intermetallic compounds and promote the formation of simple solid solution structure and even amorphous phase. The unique design concept and phase structure give the high entropy alloy nitride film excellent physical properties such as ultra-high hardness and toughness, excellent wear resistance and corrosion resistance, super-strong barrier property, etc. It shows a broad application prospect in aerospace, transportation, energy and other fields. DC/RF magnetron sputtering (DC/RF-MS) is a conventional technique for preparing high entropy alloy nitride films. However, due to the low metal ionization rate, DC/RF-MS not only loosens the microstructure and deteriorates the properties of the film, but also greatly reduces the controllability of the structure and properties of the film. Therefore, in order to obtain high performance and high entropy alloy nitride films, a synthesis technology that can provide high density plasma environment and control the film growth process is urgently needed. Recently, Chinese scientists have made important progress in this regard.

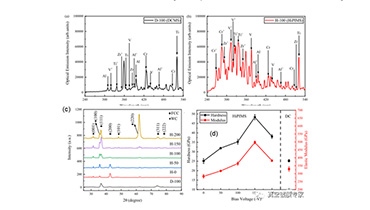

(a) DCMS plasma emission spectra; (b) HiPIMS plasma emitter spectrum, (c)XRD pattern; (d) Hardness of the high-entropy alloy prepared by HiPIMS

Al-cr-ti-v-zr-n high entropy alloy nitride system was used as the research object, and high-energy pulsed magnetron sputtering technology (HiPIMS) was used to construct high ionization rate high entropy alloy plasma film forming environment. The plasma emission spectrum showed that all the target elements in HiPIMS plasma showed a strong trend of ionization state (A), while the target elements in DCMS plasma basically existed in the form of excited state (B). At the same time, the matrix bias technology is used in the process of HiPIMS film preparation to directly drive the plasma to the matrix through the regulation of the plasma sheath, so as to realize the control of the plasma energy and flux reaching the matrix surface. The results show that the increase of plasma energy and flux can significantly enhance the ion bombardment effect, thus promoting the formation of preferred nucleation points and defects. At the same time, the mobility and etching effect of the particles deposited on the surface of the film are further improved. The prepared (AlCrTiVZr) N films all exhibit a single FCC solid solution structure. Under the effect of ion bombardment, the microstructure morphologies are glassy and exhibit (111) grain orientation preferred growth, grain size refinement (11.3 nm), and surface roughness as low as 0.4 nm. The hardness of the film reaches the superhard level (48.3 GPa) under the joint effect of structure strengthening effect, fine grain strengthening effect and boundary strengthening effect. This study systematically expounded the relationship among the spatio-temporal properties of plasma, microstructure and mechanical properties of high-entropy alloy, effectively analyzed the mechanism of ion bombardment effect in the growth process of high-entropy alloy film, and provided clues for the design and preparation of high-performance high-entropy alloy nitride film.

Through the research of Chinese scientists, the wider application of HiPIMS plasma technology in the future is further explored. HiPIMS plasma technology will also be more widely used in scientific research and industry.

18922924269

18922924269