Sputtering characteristics of HiPIMS reaction

The introduction

HiPIMS power supply has been well used in the industrial application of hard coatings with high density, but there are not many cases of optical application. This paper will introduce the characteristics of HiPIMS in reactive sputtering mode.

Dot eyeball

In reactive sputtering, the target surface poisoning phenomenon exists in DCMS. Although MF sputtering can solve the target surface poisoning phenomenon to a certain extent, the density and refractive index of the prepared film layer have room for improvement compared with that of the block material.

Whether HiPIMS sputtering technology can solve the target surface poisoning, and obtain high speed and high density film.

content

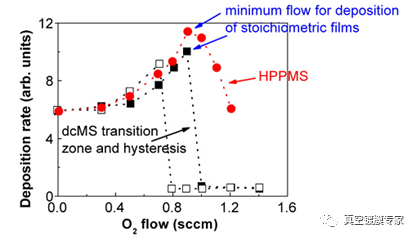

After a comprehensive study of HiPIMS reaction sputtering Al2O3 and ZrO2 [1], compared with DCMS sputtering, which has hysteresis and instability in the transition zone, DCMS obviously has O2 intake hysteresis, and the window period of oxygen content in the transition zone is very narrow, as shown in Figure 1. However, there is no hysteresis in the process of HiPIMS reaction sputtering, and the sputtering rate can be stable even in the transition zone. When the oxygen intake is optimized, the sputtering rate can be increased compared with that of DC.

Sputtering characteristics of HiPIMS reaction

Figure 1. Comparison of sputtering alumina deposition rates between DC and HiPIMS reactions

Compared with DCMS, even though the sputtering amount of materials is the same, the sputtering rate of HiPIMS is lower, mainly because the membrane layer of HPPMS is more compact.

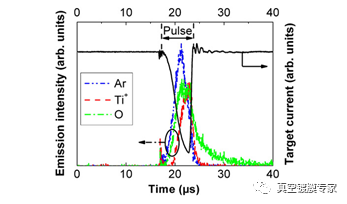

There is no hysteresis loop in the oxygenation and deoxygenation test of HiPIMS reaction sputtering. The reasons are as follows: 1. There is a high etching rate of the target in the pulse stage, while no reactants are produced on the target surface in the pulse off stage, which will not poison the target. 2. Usually, the high target voltage of HiPIMS will lead to high chemical sputtering yield, even if there are non-conductive compounds on the target surface, they can be etched away. 3. The same phenomenon of gas rarefaction not only affects Ar, but also affects the reaction gas, making the reaction gas rarefaction after ionization, as shown in Figure 2. During the pulse time, Ti ions continue to increase, while Ar or O ions gradually increase in the initial pulse 5-10 US, and then decrease with the gas rarefied effect. This increase in metal ions and the staggered production time of gas ions will be beneficial to the preparation of compounds by reactive sputtering.

HiPIMS reaction sputtering

conclusion

1) There is no hysteresis loop in the oxygenation and oxygenation test of HiPIMS reaction sputtering

2) The high metal ionization rate and high voltage in HiPIMS are conducive to the reactive sputtering process and obtain the dense optical coating

18922924269

18922924269